-

7_WSP_ACTING RESPONSIBLY:

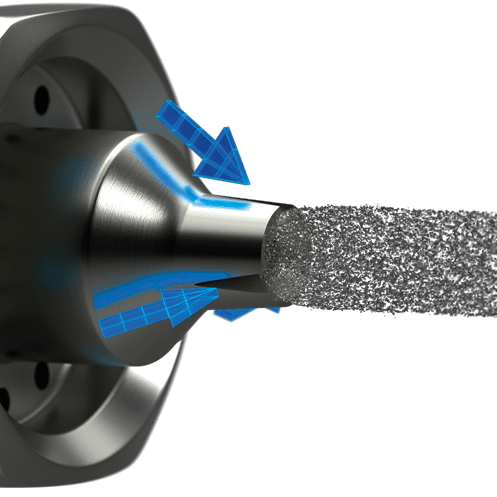

Our spray guns are designed for durability, minimizing the need for frequent replacements. This allows you to concentrate on your tasks without interruptions, enhancing your workflow and reducing downtime effectively.

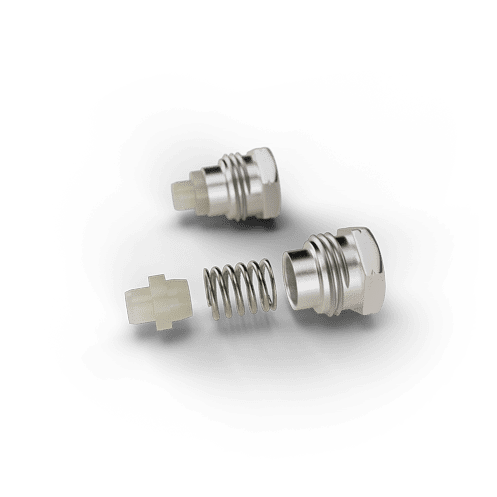

We provide a comprehensive range of spare parts for our spray guns, making repairs straightforward and economical. Choosing repairs over full replacements helps you significantly reduce costs and make the best use of your resources.

Our packaging is simple and fully recyclable. The internal tray is made from reclaimed sugarcane pulp, and we minimize printed manuals to cut waste. By choosing our products, you contribute positively to the planet.

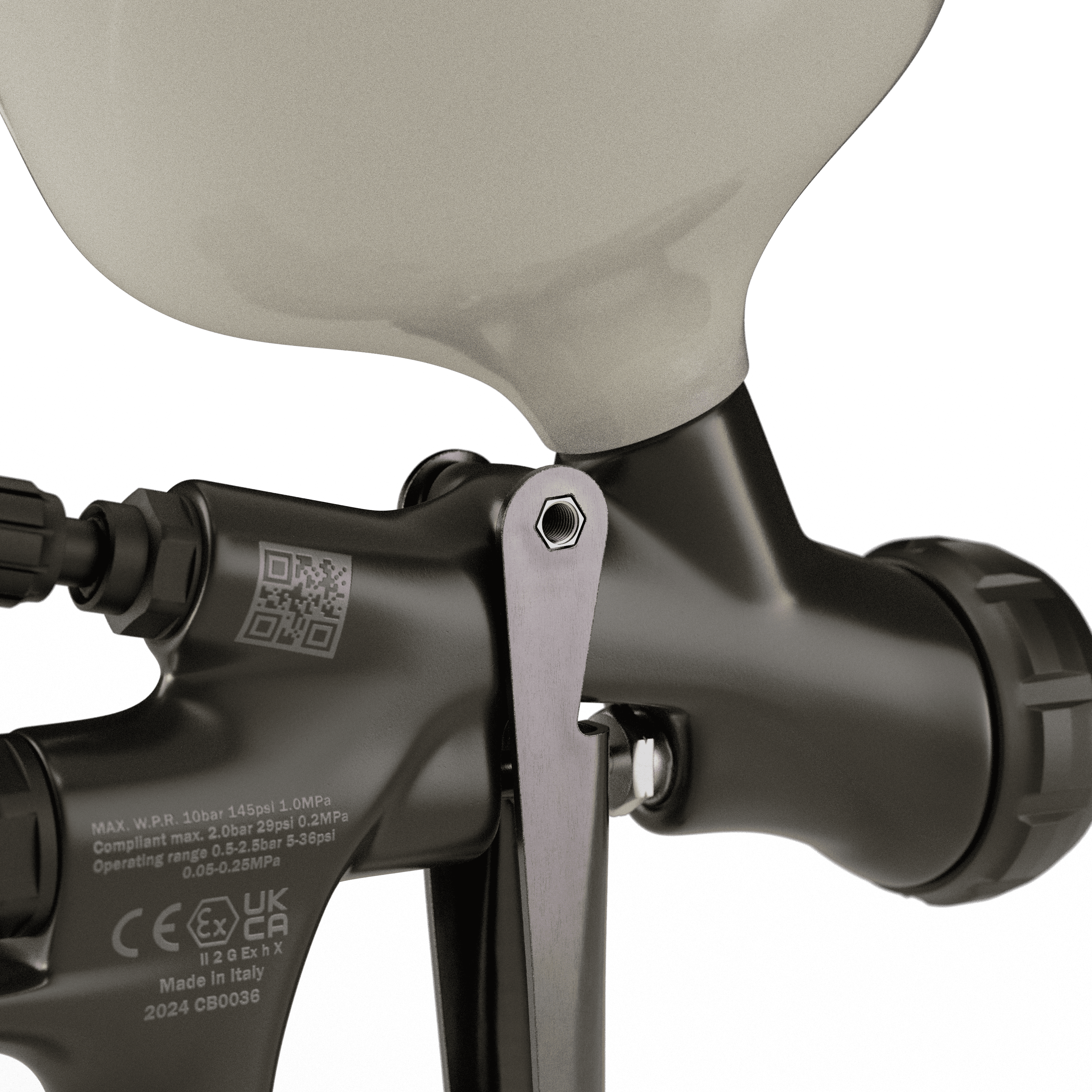

"A spray gun that applies filler as easily as wet on wet".

- Michael Dick - Kfz Dorfmeister GmbH.