-

Highlights

Baffle

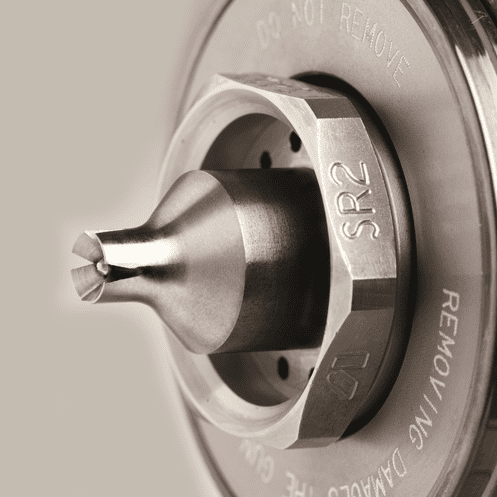

Baffle Gasketless system

Gasketless system in paint nozzle's connection

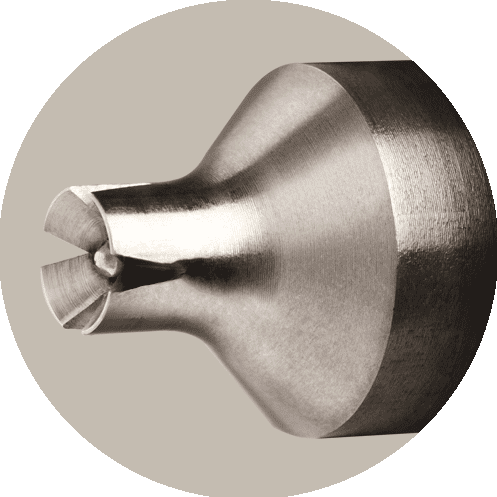

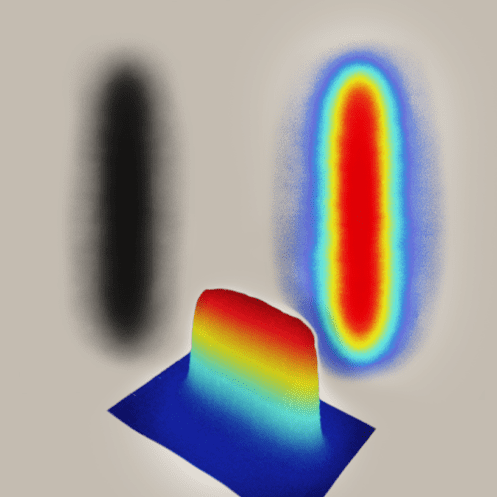

Conical

Conical Air Cap Design

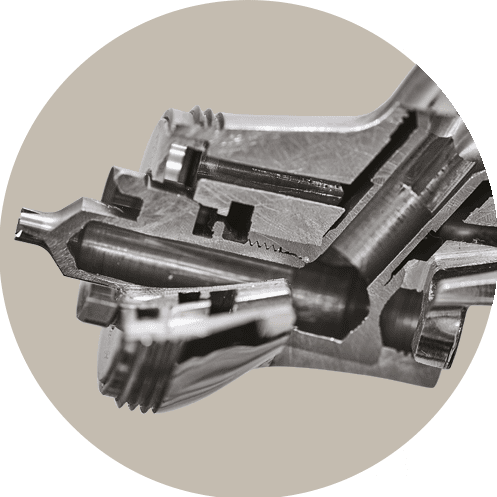

Split Nozzle 2.0

Split Nozzle™ 2.0 is the most advanced paint atomisation technology in the industry.

Refined micro-details of all moving and sensitive parts allow for the Series 2 to achieve a shorter shape and a lighter weight than the previous version. The result is the optimisation of the ergonomic experience, unrivalled by any competitor.

Thanks to improved atomisation by Split Nozzle™ 2.0 technology, our engineers are not limited by the lack of adjustable parameters that restrict traditional nozzles, allowing them to craft the perfect fan pattern.

Engineering THE WS-400 Series 2

"We wanted to create something unique in perfect Anest Iwata style. In the end we made it, creating something really special. I am proud of have been part on in this project."

- Marco Negri, Engineer Manager

Recommendation Charts

B: Brand

A: Application

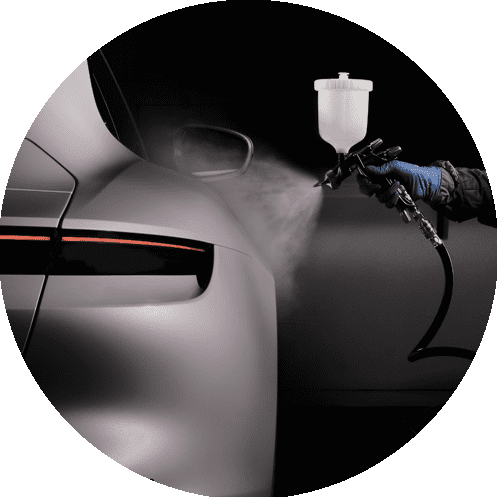

Using the WS-400 Series 2

"My first impression was absolutely positive…

it‘s lighter, faster and more even compared to its predecessor and I think we even saved some material."

- Markus Feller, Auto Christian Gmbh