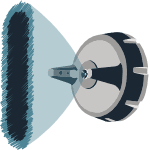

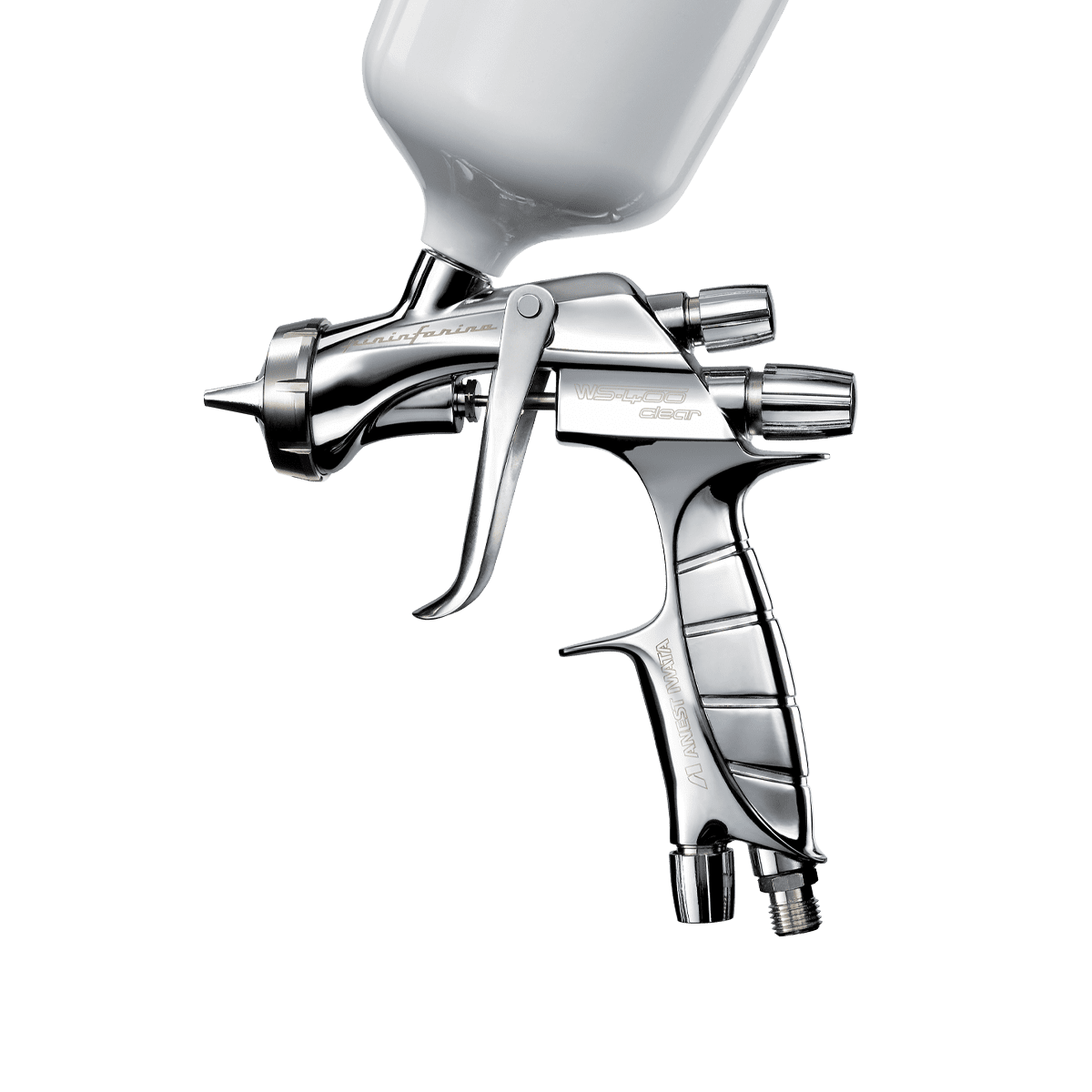

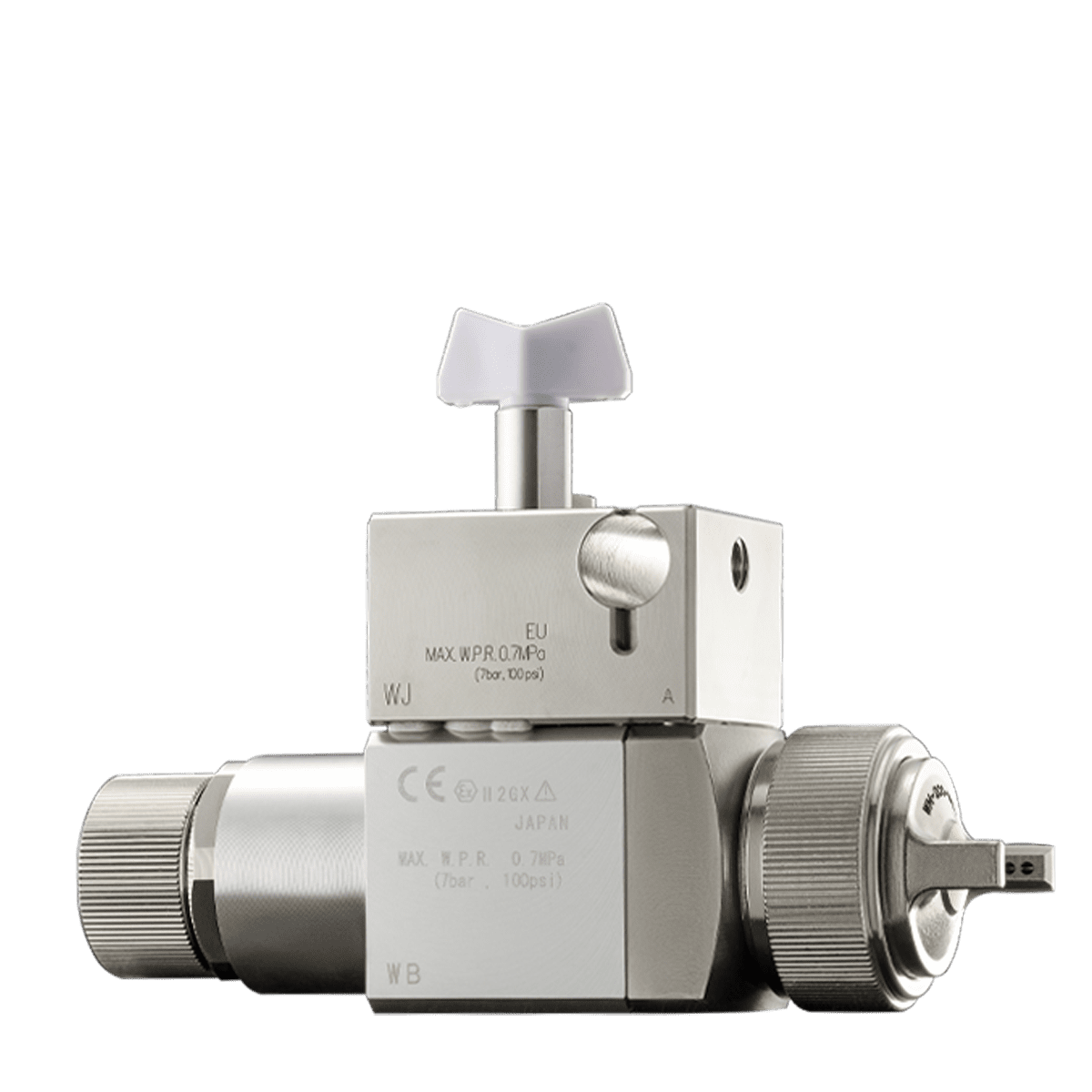

The Fan patterns of Split Nozzle Spray Guns have a very unique shape. It is perfectly even and flat with a large wet core. This helps to achieve an even laydown of paint, avoiding mottle and creates only little overspray.

Thanks to its unique fan pattern shape and the evenly distributed droplets our Split Nozzle technology helps you to apply just the right amount of paint and even helps you to save material. This keeps the costs low and the quality high.

The low noise levels of the split nozzle technology make working in a spray-painting environment easy and relaxing. Helping you to deliver perfect results every time.